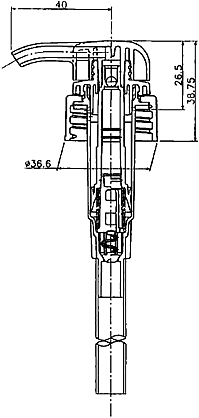

5cc/3cc pump dispenser

|

|

| K501 |

|---|

Features

- Water influx prevention structure

[purpose]

Since there are times when using the pump in the shower etc., water enters the pump, it Reduces the risk of fluid alteration to the content.

[method]

Since the upper cap is structured by external thread, it minimizes the clearance between the piston shaft and upper cap. the point of water influx is closer to the ejector head, comparing water influx system of other companies, our gives a much better result.

- back suction

[purpose]

when the liquid content is at the tip of the nozzle, to prevent dripping the nozzle solidification causes no dripping(jumping of the liquid content etc.) and reduces the risk.

[Method]

After discharging the liquid contents, the internal mechanism of the ejector head brings back the liquid content from the nozzle tip. - Safety improvement * PL measures

* Ejector head opening angle - (to be kept at 270 degrees)

Increase in transit and the above opening angle of the ejector head might result in leakage or By loosening the head of the ejector at a store. To prevent leakage of liquid contents the above need to be kept in mind. The nozzle is safe even in case of a fall. Because of the base of the nozzle it is better compared to other products. The quality is top level. For the The tip of ejector head`s nozzle we use a R as the safety measure for PL. As compared to other similar products delicate and tiny parts are not used. Structure is simple,which helps in realizing high Quality and Stable production . - Light Pressing

As compared to other similar products, we provide a light and smooth feel press. - Weight of the product

Compared with competitors, We aim to reduce the weight,

Specification table

| Material | PP,PE,SUS |

|---|---|

| Mechanism | Direct Pressure |

| Dosage | 5cc |

| No. of pieces | Tube lenght135mm below-500 pcs; tube length 135mm above-400 pcs |

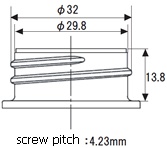

| Recommended bottle mouth size |

|

Components

| No. | component | material | color |

|---|---|---|---|

| 1 | ejector head | PP | B type |

| 2 | upper cap | PP | B type |

| 3 | container cap | PP | - |

| 4 | piston shaft | PE | - |

| 5 | seal valve | PE | - |

| 6 | accumulator | PP | - |

| 7 | ball | SUS | - |

| 8 | spring | SUS | - |

| 9 | gasket | mold packing/ highsheet |

- |

| 10 | Tube | PE | - |

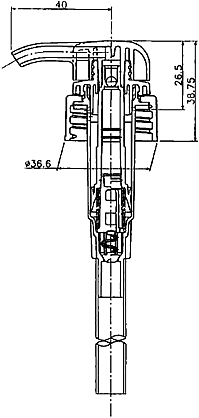

[outline]

|

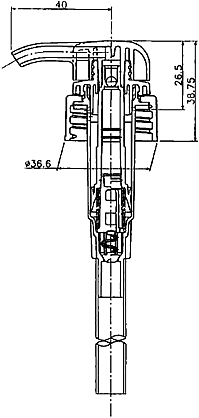

|

| K301 |

|---|

Features

- Water influx prevention structure

[purpose]

Since there are times when using the pump in the shower etc., water enters the pump, it Reduces the risk of fluid alteration to the content.

[method]

Since the upper cap is structured by external thread, it minimizes the clearance between the piston shaft and upper cap. the point of water influx is closer to the ejector head, comparing water influx system of other companies, our gives a much better result.

- back suction

[purpose]

when the liquid content is at the tip of the nozzle, to prevent dripping the nozzle solidification causes no dripping(jumping of the liquid content etc.) and reduces the risk.

[Method]

After discharging the liquid contents, the internal mechanism of the ejector head brings back the liquid content from the nozzle tip. - Safety improvement * PL measures

* Ejector head opening angle - (to be kept at 270 degrees)

Increase in transit and the above opening angle of the ejector head might result in leakage or By loosening the head of the ejector at a store. To prevent leakage of liquid contents the above need to be kept in mind. The nozzle is safe even in case of a fall. Because of the base of the nozzle it is better compared to other products. The quality is top level. For the The tip of ejector head`s nozzle we use a R as the safety measure for PL. As compared to other similar products delicate and tiny parts are not used. Structure is simple,which helps in realizing high Quality and Stable production . - Light Pressing

As compared to other similar products, we provide a light and smooth feel press. - Weight of the product

Compared with competitors, We aim to reduce the weight,

Specification table

| Material | PP,PE,SUS |

|---|---|

| Mechanism | Direct Pressure |

| Dosage | 3cc |

| No. of pieces | Tube lenght135mm below-500 pcs; tube length 135mm above-400 pcs |

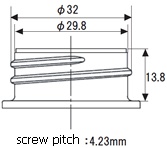

| Recommended bottle mouth size |

|

Components

| No. | component | material | color |

|---|---|---|---|

| 1 | ejector head | PP | B type |

| 2 | upper cap | PP | B type |

| 3 | container cap | PP | - |

| 4 | piston shaft | PE | - |

| 5 | seal valve | PE | - |

| 6 | accumulator | PP | - |

| 7 | ball | SUS | - |

| 8 | spring | SUS | - |

| 9 | gasket | mold packing/ highsheet |

- |

| 10 | Tube | PE | - |

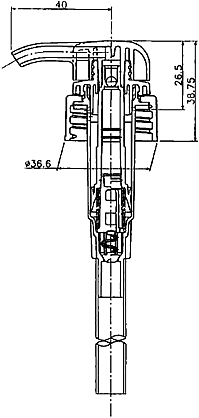

[outline]

Inquiries about products and services

Please feel free to contact us by phone or by email for any comments or suggestions about our products (+81-72-634-3597)